I. ISO 2859-1 (MIL-STD-105E) Standard

What Is ISO 2859-1 (MIL-STD-105E) Standard?

ISO 2859-1, also known as MIL-STD-105E, is an international standard for sampling procedures and tables used in quality inspection by attributes.

It provides guidelines for determining the acceptable quality level (AQL) for a given lot of products.

The standard specifies various sampling plans based on the lot size and desired level of inspection.

These plans outline the number of samples to be inspected and the acceptance and rejection criteria based on the number of defects found in the samples.

The goal of ISO 2859-1 is to provide a statistically reliable method for evaluating the quality of a production lot, ensuring that it meets the desired quality requirements.

Benefits Of ISO 2859-1 (MIL-STD-105E) Standard

The ISO 2859-1 (MIL-STD-105E) standard offers several benefits in quality inspection and assurance. Some of the key benefits include:

- Standardized Sampling Procedures:

The standard provides a systematic and standardized approach to sampling, ensuring consistency and comparability across different inspection processes and organizations.

This facilitates effective communication and understanding between manufacturers, suppliers, and customers.

- Reliable Quality Evaluation:

ISO 2859-1 enables statistically reliable quality evaluation by providing sampling plans based on lot size and desired inspection level.

This helps to ensure that the inspected samples accurately represent the quality of the entire production lot.

- Efficient Quality Control:

The standard allows for efficient quality control by determining the appropriate sample size for inspection based on the lot size.

This helps optimize resources and time while still providing a reliable assessment of the product quality.

- Acceptable Quality Level (AQL) Determination:

ISO 2859-1 helps in determining the acceptable quality level (AQL) for a given production lot.

AQL specifies the maximum number of defects or nonconforming items that are considered acceptable within the defined sampling plan, thus assisting in setting quality targets.

Consistent Decision-Making:

The standard provides clear acceptance and rejection criteria based on the number of defects found in the inspected samples.

This promotes consistent decision-making during quality inspections and reduces subjectivity, ensuring fairness and objectivity in evaluating product quality.

Supplier-Customer Relationships:

ISO 2859-1 facilitates effective communication and understanding between suppliers and customers regarding quality expectations and requirements.

It provides a common framework for quality evaluation, enabling better collaboration and alignment between stakeholders.

Quality Improvement:

By implementing ISO 2859-1, organizations can identify areas of improvement in their production processes and work towards enhancing product quality.

The standard helps to highlight quality issues, measure performance, and drive continuous improvement initiatives.

Regulatory Compliance:

Adhering to ISO 2859-1 demonstrates a commitment to quality assurance and can assist in meeting regulatory requirements.

Compliance with recognized standards enhances credibility and confidence in the product’s quality, both internally within the organization and externally with customers and regulatory bodies.

II. Sampling procedures and tables

What Is Sampling Procedures

Sampling procedures refer to the methods and techniques used to select a representative subset, or sample, from a larger population or lot for the purpose of inspection, analysis, or evaluation.

Sampling is a practical approach to assessing the quality or characteristics of an entire population without inspecting every single unit, which may be time-consuming, costly, or impractical.

The procedures of aluminum cosmetic containers sampling involve the following steps:

Sampling Standard:

Select an appropriate sampling standard like ISO 2859-1(Mil Std 105E) Standard based on the nature of the population and the objectives of the study.

Sample Selection:

Select aluminum cosmetic containers quantity according to the ISO 2859-1(Mil Std 105E) Standard.

This ensures that each unit has an equal or known chance of being included in the sample.

Sample Analysis:

Analyze the collected data to draw conclusions or make inferences about the entire population.

Normally, analysis of aluminum cosmetic containers includes the following aspects:

- Inspect the size of aluminum cosmetic containers’ body and neck

- Inspect the thickness of the aluminum cosmetic containers.

The thickness of aluminum cosmetic bottles by automatic production line is 0.4mm, and by semi-automatic production line is 0.5-0.55mm.

The thickness of aluminum cosmetic bottles by automatic production line is 0.4mm, and by semi-automatic production line is 0.5-0.55mm. - Inspect the surface quality of the aluminum cosmetic containers

- Inspect the rolling teeth, if there is a burr around the bottleneck

- Inspect the printing quality especially the font and image quality on the aluminum cosmetic containers

- weigh the aluminum cosmetic container normally 15-60g

Interpretation and Decision-Making:

Interpret the results obtained from the sample analysis and make informed decisions or draw conclusions about the population.

This may involve comparing the sample findings with predetermined criteria or standards.

Sampling procedures are widely used in various fields, including manufacturing, quality control, market research, opinion polling, medical studies, and environmental monitoring.

By using appropriate sampling procedures, organizations can efficiently gather information, assess quality, identify trends, and make informed decisions

How To Find The Corresponding Lot Size And Inspection Level For Aluminum Bottles?

To determine the corresponding lot size and inspection level for aluminum bottles according to ISO 2859-1 (MIL-STD-105E), you need to consider the following factors:

1. Quality Requirements:

Determine the quality requirements or acceptable quality level (AQL) for the aluminum bottles.

This specifies the maximum number of defects or nonconforming items that are considered acceptable.

2. Sampling Plan:

Refer to the sampling plan provided in ISO 2859-1, which consists of tables or charts that define the sample size and acceptance/rejection criteria based on the lot size and inspection level.

3. Lot Size:

Determine the total number of aluminum bottles in the production lot or batch.

This could be based on the manufacturing process, production order, or other relevant factors.

4. Inspection Level:

Choose the appropriate inspection level based on the desired level of inspection rigor.

ISO 2859-1 provides three general inspection levels: I, II, and III, with Level I being the least rigorous and Level III being the most rigorous.

5. Find the Corresponding Sampling Plan:

Use the tables or charts provided in ISO 2859-1 to locate the corresponding sampling plan based on the determined lot size and inspection level.

These tables provide the sample size and acceptance/rejection criteria for different combinations of lot size and inspection level.

By referring to the appropriate sampling plan, you can determine the sample size (number of bottles to be inspected) and the acceptance/rejection criteria (number of allowable defects) based on the lot size and inspection level chosen.

This ensures that you have a statistically reliable method to evaluate the quality of the aluminum bottles in the production lot.

III. Limitations and alternative standards

Potential limitations of ISO 2859-1 for aluminum bottle inspection

While ISO 2859-1 (MIL-STD-105E) is a widely recognized and effective standard for sampling procedures and inspection, it does have some potential limitations when applied to aluminum bottle inspection. These limitations include:

Limited Scope of Defects:

ISO 2859-1 provides general guidelines for sampling and inspection, but it does not offer specific criteria for all possible defects that may be relevant to aluminum bottles.

This may require additional specifications or industry-specific standards to address specific defects or nonconformities related to aluminum bottles.

Surface Defects vs. Structural Defects:

The standard primarily focuses on surface defects and visual inspection criteria.

However, some defects in aluminum bottles may be structural or functional in nature, such as leaks, improper sealing, or dimensional inaccuracies.

ISO 2859-1 may not fully address these types of defects, requiring additional testing or inspection methods.

Sampling Variability:

Sampling introduces inherent variability, as inspection results are based on a subset of the production lot.

The sample may not capture all potential defects or accurately represent the overall quality of the lot.

This variability may lead to different conclusions or decisions based on different samples from the same lot.

Lack of Contextual Factors:

ISO 2859-1 does not consider contextual factors that may influence the acceptability of defects in aluminum bottles.

Factors such as the intended use of the bottles, customer requirements, regulatory standards, and specific industry considerations may require additional criteria or adjustments beyond what the standard provides.

Subjectivity in Defect Classification:

The standard’s acceptance and rejection criteria are often based on subjective judgment and interpretation of defects.

Different inspectors may have varying interpretations, leading to inconsistency in inspection results.

This subjectivity can be minimized through thorough training and establishing clear guidelines for defect classification.

Single-Level Inspection:

ISO 2859-1 offers a single inspection level for each lot size, limiting flexibility in adjusting the level of inspection based on specific requirements or circumstances.

Certain situations may require more or less rigorous inspection, which may not be accommodated by the standard’s fixed inspection levels.

Other standards or approaches for quality assurance in aluminum bottle manufacturing

In addition to ISO 2859-1 (MIL-STD-105E), there are other standards and approaches that can be considered for quality assurance in aluminum bottle manufacturing. Some of these include:

ISO 9001:

The ISO 9001 standard provides a comprehensive framework for implementing a quality management system (QMS) in any organization.

It focuses on ensuring consistent product quality, customer satisfaction, and continuous improvement.

Implementing ISO 9001 can help aluminum bottle manufacturers establish robust quality control processes and maintain overall quality management.

ISO 15378:

This standard specifically addresses the quality management system requirements for manufacturers of primary packaging materials for medicinal products.

ISO 15378 provides guidelines for ensuring the quality, safety, and compliance of packaging materials, including aluminum bottles, used in the pharmaceutical industry.

Good Manufacturing Practices (GMP):

GMP regulations are industry-specific guidelines that define the requirements for the production, packaging, and quality control of various products, including pharmaceuticals, food, and cosmetics.

Adhering to GMP principles ensures that manufacturing processes and quality control measures are in compliance with regulatory standards and industry best practices.

ASTM International Standards:

ASTM International develops and publishes voluntary consensus standards for various industries, including packaging materials.

Aluminum bottle manufacturers can refer to ASTM standards related to material properties, performance testing, dimensions, and other relevant criteria to ensure the quality and consistency of their products.

IV. Conclusion

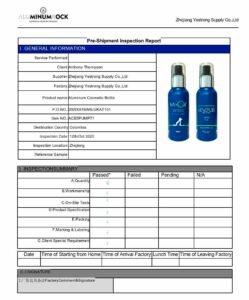

Even most Chinese aluminum bottle manufacturers have in-house inspection workers.

Normally, they inspect aluminum cosmetic containers daily with their own standard. It includes bottle Neck, rolling teeth, printing, etc.

However, we as customers have our own quality control personnel to sample inspection to minimize losses.

Aluminumrock has an inspection team applying ISO 2859-1(Mil Std 105E) AQL standard, pre-shipment inspection will be strictly adopted.

To save you time, you can contact our sales representatives for aluminum cosmetic bottles. Aluminumrock is your reliable vendor for your brand and business.

One Response

quos est dolor est sint fuga sapiente eligendi. dolore eum enim consequuntur adipisci magnam est.