Quality Is Guaranteed

The cold extrusion seamless forming of ALUMINUMROCK’s aluminum cosmetic container assures zero leakage in even the most demanding applications.

We also manufacture Anti-theft cap aluminum bottles which are moderate choices in the cosmetic and industry field.

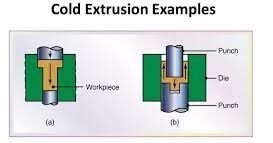

Cold extrusion seamless forming

Cold extrusion seamless forming is a manufacturing process used to create seamless aluminum cosmetic containers.

This process involves shaping a solid billet of aluminum into the desired container shape without the need for welding or joining processes.

The main advantage of cold extrusion seamless forming is that it produces containers with a seamless and smooth finish, providing an attractive appearance for cosmetic products.

Here is a general overview of the cold extrusion seamless forming process for aluminum cosmetic containers:

Billet Preparation:

A solid cylindrical billet of aluminum is selected, which is typically made from a high-quality aluminum alloy suitable for cosmetic containers.

The billet is cut to the appropriate length for forming the container.

The billet is cut to the appropriate length for forming the container.

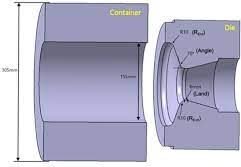

Container Design and Die Preparation:

The desired container shape is designed, taking into consideration the size, dimensions, and aesthetics.

A die is then prepared, which consists of a stationary outer mold and an inner punch.

Lubrication:

Before the extrusion process, the billet and the die are coated with a lubricant to facilitate smooth movement and prevent sticking.

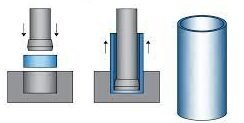

Cold Extrusion Process:

The billet is placed inside the die, and the punch applies pressure to the billet, forcing it to flow and take the shape of the inner mold.

This process is performed at room temperature, hence the term “cold” extrusion.

The pressure applied can be hydraulic or mechanical, depending on the specific equipment and requirements.

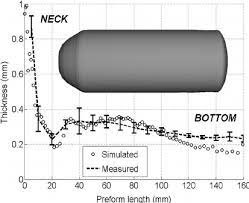

Forming and Wall Thickness Control:

As the billet flows under pressure, it gradually takes the shape of the inner mold, forming the container.

The wall thickness of the container is controlled by the design of the die and the amount of material present in the billet.

Finishing Operations:

After the extrusion process, the formed container may undergo additional operations to refine its shape, such as trimming excess material, smoothing the surface, and adding decorative elements.

Surface Treatment:

The formed containers can undergo various surface treatments, including anodizing, polishing, or coating, to enhance their appearance, protect against corrosion, and improve durability.

Inspection and Quality Control:

The finished containers are inspected to ensure they meet the required specifications, including dimensions, wall thickness, and surface quality.

Defective containers are identified and removed from the production line.

What Is ISO 2859-1(Mil Std 105E) Standard For Aluminum Bottle

By utilizing cold extrusion seamless forming, manufacturers can produce high-quality aluminum cosmetic containers with a seamless appearance, superior strength, and precise dimensions.

These containers are commonly used in the cosmetic industry due to their aesthetic appeal, durability, and corrosion resistance.

Download Aluminum Bottles Brochure

Aluminum Cosmetic Bottle Characteristics

Aluminum cosmetic bottles are a popular choice in the cosmetic industry due to their lightweight, durable, and corrosion-resistant properties.

They offer impermeability to air, light, and moisture, preserving the quality of cosmetic products. Aluminum is recyclable, aligning with the demand for sustainable packaging solutions.

These bottles are customizable, allowing for branding and design flexibility. They exhibit temperature stability and can provide UV protection to light-sensitive products.

Additionally, aluminum bottles are hygienic, as they are non-porous and easy to clean.

Aluminum Cosmetic Containers Size

Different shapes of aluminum cosmetic containers correspond to different diameters of height.

Aluminum Cosmetic Containers Applications

Aluminum cosmetic containers have a wide range of applications in the cosmetic industry. Here is the typical industry in which ALUMINUMROCK aluminum cosmetic bottles are used for:

Skincare Plant

- Lotions

- Serums

- Hand Sanitizer

Haircare Plant

- Shampoos

- Conditioners

- Hair masks

- Styling products

Perfumes and Fragrances

- Perfumes

- Colognes

Makeup Products

- Foundation

- Blush

- Eyeshadow

- Lipstick

Deodorants and Antiperspirants

- Deodorants

- Antiperspirants

Sunscreens

- Sunscreen lotions

- Cream

Need Quotation For Your Project? Contact Now!

Personal Care Products

- Body lotions

- Body oils

- Shower gels

- Body scrubs

How To Select Aluminum Bottles In Cosmetic And Skincare Plants

When selecting aluminum bottles for cosmetic and skincare plants, it’s essential to consider several factors as follows:

Please find the complete article as following:

How To Select Aluminum Bottles In Cosmetic And Skincare Plants

Contact us to get a quotation for aluminum cosmetic containers now.