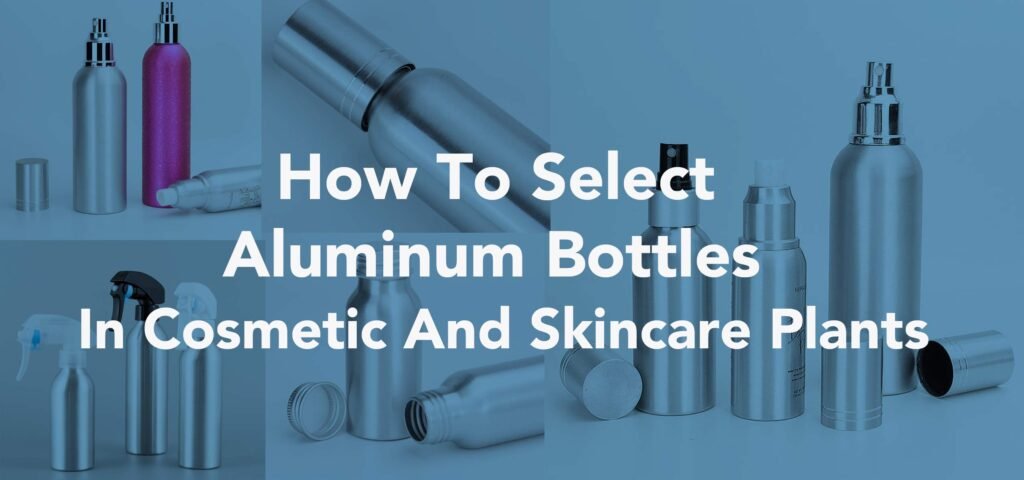

When selecting aluminum bottles for cosmetic and skincare plants, it’s essential to consider several factors as follows:

1. Analysis Of The Reasons For The Performance Of Aluminum Bottles In Cosmetic And Skincare Plants.

1.1. characteristics of Aluminum Bottles

Aluminum bottles are lightweight, durable, and resistant to corrosion, which makes them an excellent packaging material for cosmetic and skincare products.

They can be shaped into a variety of sizes and designs, providing flexibility in packaging design.

Aluminum bottles are also impermeable to gases and liquids, protecting the product from external factors such as oxygen, moisture, and UV radiation.

This characteristic makes them ideal for packaging sensitive cosmetic and skincare products that can be affected by these external factors.

1.2. Lightproofness of Aluminum Bottles

They have excellent lightproofness, which means that they can protect the product from exposure to light.

Exposure to light can cause some cosmetic and skin care products to degrade, discolor, or lose their effectiveness.

Aluminum bottles can help preserve the quality of the product by blocking out light, making them a popular choice for products that are sensitive to light, such as vitamin C serums, retinoids, and other active ingredients.

1.3. Recyclability of Aluminum Bottles

Aluminum is highly recyclable, and aluminum bottles can be recycled repeatedly without losing their quality.

This makes them a sustainable choice for packaging cosmetic and skincare products.

The recycling process for aluminum requires less energy compared to other materials, such as plastic or glass, and recycling aluminum can help reduce greenhouse gas emissions.

Additionally, aluminum bottles are often made from a high percentage of recycled aluminum, further reducing the environmental impact of packaging

2. Comparison Among Aluminum Bottles, Glass Bottles, and Plastic Bottles For Cosmetic And Skincare Products.

2.1. What Are Aluminum Bottles?

Aluminum bottles are a relatively new packaging option for cosmetic and skincare products.

They are lightweight, durable, and have excellent barrier properties, protecting the product from external factors such as light, air, and moisture.

What Is ISO 2859-1(Mil Std 105E) Standard For Aluminum Bottle

Aluminum bottles are made from recycled aluminum, making them a more sustainable option than plastic.

2.1.1. Benefits Of Aluminum Bottles

Aluminum bottles are lightweight, making them easy to transport and store.

They have excellent barrier properties, protecting the product from external factors such as light, air, and moisture.

They are also highly recyclable, making them a sustainable option for packaging.

Additionally, aluminum bottles have a high-end aesthetic appeal and can be designed to provide a unique look and feel for the product.

2.2. What Are Glass Bottles?

Glass bottles are a popular choice for packaging cosmetic and skincare products due to their visual appeal and perceived high-end quality.

They are made from natural raw materials such as sand, soda ash, and limestone, making them a more eco-friendly option than plastic.

Glass bottles come in a variety of shapes and sizes, and they are inert and do not react chemically with the contents, making them ideal for storing high-quality products.

2.2.1. Benefits Of Glass Bottles

Glass bottles have excellent barrier properties, making them an ideal choice for products that require protection from light, air, and moisture.

They are also recyclable and can be used repeatedly without losing their quality.

Glass bottles do not contain any harmful chemicals and are considered a safer option for packaging compared to plastic bottles.

2.3. What Are Plastic Bottles

Plastic bottles are widely used in the cosmetic and skincare industry due to their versatility, lightweight, and affordability.

They are made from petrochemicals, making them a non-renewable and non-biodegradable material.

Plastic bottles come in a variety of shapes and sizes, and they can be designed to provide a unique aesthetic appeal.

2.3.1. Benefits Of Plastic Bottles

Plastic bottles are lightweight, making them easy to transport and store.

They are also shatterproof, making them a safer option than glass bottles.

Plastic bottles are also more affordable than glass bottles, making them an attractive option for businesses on a budget.

3. Comparison

These differences below can impact the choice of bottle material for cosmetic and skin care products, depending on the specific needs and requirements of the product and brand.

| Feature | Aluminum Bottles | Glass Bottles | Plastic Bottles |

|---|---|---|---|

| Material | Recycled aluminum | Sand and soda ash | Petrochemicals |

| Weight | Lightweight | Heavy | Lightweight |

| Durability | Durable | Fragile | Less durable |

| Barrier properties | Excellent | Excellent | Moderate |

| Recyclability | Highly | Highly | Moderate |

| Eco-friendliness | Sustainable | Eco-friendly | Non-biodegradable |

| Chemical reaction | None | None | May react |

| Aesthetic appeal | High-end | High-end | Versatile |

| Cost | Moderate | Expensive | Affordable |

4. Recommendations For Manufacturing Inspection Requirements For Aluminum Bottles

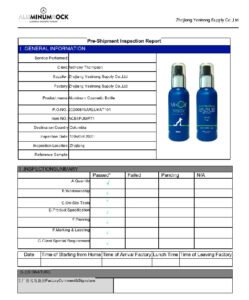

Most Chinese Manufacturing inspection standard follows the SGS ISO 2859-1(Mil Std 105E) standard.

Here are some recommendations for manufacturing inspection requirements for aluminum bottles:

Material inspection:

The raw materials used for manufacturing aluminum bottles should be inspected thoroughly before production to ensure they meet the required quality standards.

Aluminum bottles’ raw materials include aluminum slug, paint, and lacquers.

The main Inspection of aluminum slugs is to weigh the slug.

The main Inspection of paint and lacquers is to compare the color with the standard color chart like Pantone.

Quality control during manufacturing:

Quality control measures should be implemented during the manufacturing process to detect any defects or issues with the bottles.

This includes inspecting the bottles for any burrs, dents, scratches, or other defects.

Labeling and printing inspection:

The labeling and printing of the bottles should be inspected to ensure they meet the required regulations and standards.

Printing colors should be printed uniform, the font shouldn’t be stretched deformation, etc.

Sampling and testing:

Regular sampling and testing of the finished bottles should be conducted to ensure they meet the SGS ISO 2859-1(Mil Std 105E) standards.

Aluminumrock owns an in-house inspection team to do the inspection with daily work, random inspection, pre-shipment inspection, etc.

Get the complete pre-shipment inspection report for one of our clients

Documentation:

Proper documentation of the production process, inspection results, and testing should be maintained for record-keeping purposes.

By implementing these manufacturing inspection requirements, cosmetic and skincare plants can ensure the quality and safety of their products and build trust with their customers.

5. Recommendations Aspects For Matching The Material Of The Aluminum Bottles

When selecting aluminum bottles for cosmetic and skincare plants, it’s essential to consider several factors to ensure the bottles meet your specific needs.

Here’s a step-by-step guide to help you in the selection process:

5.1. Determine your requirements:

Clearly define your requirements and expectations for the aluminum bottles.

Consider factors such as bottle size, capacity, shape, closure type, and any specific features you may need for your cosmetic and skincare products.

5.2. Evaluate bottle specifications:

Look for aluminum bottles that meet the necessary specifications for your products.

Consider aspects such as the bottle’s capacity (in ounces or milliliters), dimensions, and neck size.

Ensure that the bottles are compatible with your production line and packaging equipment.

5.3. Material considerations:

Assess the quality and properties of the aluminum used in the bottles.

Look for high-quality aluminum that offers excellent corrosion resistance to ensure the integrity and longevity of your products.

Additionally, check if the bottles are made from food-grade aluminum to comply with regulatory requirements for cosmetic and skincare products.

5.4. Closure options:

Consider the closure types available for the aluminum bottles.

Depending on your specific needs, you may require screw caps, sprayers, pumps, or dropper caps.

Ensure that the closure options are compatible with the bottles and offer a secure and leak-proof seal to maintain product integrity.

Here is an Ultimate Guide for All Closures of Caps For Aluminum Cosmetic Bottles

5.5. Customization and branding:

If branding is important to your cosmetic and skincare products, check if the aluminum bottles can be customized.

Look for options such as embossing, debossing, labeling, or printing to display your brand name, logo, or product information effectively.

5.6. Regulatory compliance:

Ensure that the aluminum bottles meet the necessary regulatory standards and requirements for cosmetic and skincare products.

This includes considerations for food-grade materials, labeling requirements, and any specific regulations in your target markets.

5.7. Sample and testing:

Before making a bulk purchase, request samples of the aluminum bottles to assess their suitability for your products.

Conduct tests to check compatibility with your formulas, ease of use, and any other factors that are critical for your specific application.

5.8. Supplier assessment:

Research and select reputable suppliers who specialize in manufacturing aluminum bottles for the cosmetic and skincare industry.

Ensure they have a track record of delivering high-quality products, offer reliable customer support, and can accommodate your production needs.

5.9. Cost considerations:

Finally, evaluate the pricing of the aluminum bottles, considering your budget and the overall value they offer.

Compare prices from different suppliers, but remember to prioritize quality and suitability for your products over cost alone.

By following these steps, you can select aluminum bottles that meet your cosmetic and skincare plant’s requirements in terms of functionality, aesthetics, regulatory compliance, and brand representation.

6. Recommendations Manufacturers For Aluminum Bottles In Cosmetic And Skincare Plants.

A lot of Chinese customization companies have a wide variety of cosmetic products. Aluminum cosmetic packages are not their only products.

Most of them recently added Aluminum cosmetic materials to their inventory. As a result, during customization, their printing lacks professionalism.

Making a professional and reliable aluminum cosmetic bottle customization company is important. They are hard to find. But we have done the hard work for you.

Here we list the top 8 aluminum cosmetic bottles customization companies in China are:

- AluminumRock

- Shining Aluminum Packaging

- B.I. Industrial

- E-better Packing

- Ever Bright Industrial

- Sky Commodity

- Passen Pack

- Merrynewon Daily Necessities

This is the article for Top 8 Aluminum Cosmetic Bottles Manufacturers In China

We hope you are enjoying this guide to find a satisfied material for your products.

To save you time, you can contact our sales representatives for aluminum cosmetic bottles. Aluminumrock is your reliable vendor for your brand and business.

Specifications Of AluminumRock’s Aluminum Bottles

- Material: 99.7% aluminum

- Cap: screw caps, trigger sprayers, and lotion pumps in aluminum, oxide, and plastic material.

- Capacity(ml): 25 -1000

- Diameter(mm): 25 – 80

- Height(mm): 60 – 240

- Thickness(mm): 0.5 – 0.8

- Surface finish: Polishing, Color painting, Screen printing, Heat transfer printing

- Inspection And Testing: CE, SGS, FDA

One Response

You have observed very interesting points! ps nice internet site.Blog money