Aluminum screw cap bottles are a popular choice for beverage, skincare, and cosmetic packaging due to their durability, lightweight, and eco-friendliness.

These bottles are reusable and recyclable. This makes them an excellent choice for companies looking to reduce their environmental footprint.

In fact, aluminum is one of the most recycled materials in the world, with an average recycling rate of 75%.

I. Characteristics of Aluminum Screw Cap Bottles

- Durability

- Lightweight

- Eco-friendliness

- Corrosion resistance

II. Benefits of Aluminum Screw-Top Bottles

- Reusability and recyclability

- Environmental friendliness

- Easy transportation

- Cost-effectiveness

III. How Aluminum Screw Cap Bottles are Made

The manufacturing process of aluminum screw cap bottles typically involves the following steps:

Extrusion:

The first step is to produce aluminum sheets or coils through an extrusion process. The aluminum is heated and passed through a die to create the desired shape.

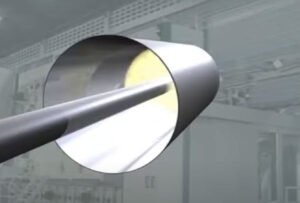

Necking:

The aluminum sections are formed into the shape of a bottle using a series of dies and presses.

This process involves stretching the aluminum into the desired shape, with the neck of the bottle being formed separately.

At AluminumRock, we have a 42-Station necking technology. This technology contains an embossing process.

This can be used to create almost any kind of shape of an aluminum skincare bottle with screw cap.

Trimming&Screw:

The excess aluminum is trimmed off the edges of the bottle, and the bottle is cleaned and polished to remove any sharp edges or rough surfaces.

https://www.youtube.com/watch?v=U7_4e675TfsWashing:

Wash the aluminium screw cap containers to clear the full containers, then it is available for coating in the following step.

The aluminum containers will be washed automatically.Inner Coating:

The inner coating consists of fusion-bonded epoxy. It provides low frictional resistance in the containers and also prevents encrustation.

Our inner coating machine has nine (9) spray guns, and each container is sprayed three (3) times during production.

Printing and Labeling:

The final step is to print and label the bottle with the desired branding, product information, and other relevant details.

There are many printing solutions for aluminum screw cap bottles, this is an article based on the difference better the Silkscreen Printing and Offset Printing

IV. Uses of Aluminum Screw Cap Bottle

Aluminum screw cap bottles are commonly used as packaging for a wide range of beverages, including:

Beer:

Many breweries use aluminum screw cap bottles to package their beer, providing a lightweight and durable option that is easy to transport and store.

Soft drinks:

Aluminum screw cap bottles are also a popular choice for soft drink packaging, as they can be easily customized with branding and labeling to create a unique and eye-catching product.

Energy drinks:

The durability and portability of aluminum screw cap bottles make them an ideal choice for packaging energy drinks, often consumed on the go.

Water:

Aluminum screw cap bottles are also used for packaging bottled water, as they provide a lightweight and convenient option for consumers who prefer to drink water on the go.

Aside from beverage packaging, aluminum screw cap bottles can also be used for a variety of other purposes, including:

Cosmetics:

Many cosmetic companies use aluminum screw-top bottles to package their products, as they provide a lightweight and durable option that is easy to transport and store.

This is an article of 7 Must-Know Key Points Import and Customize Metal Containers From China

may help with your procurement work.Pharmaceuticals:

Aluminum screw cap bottles can also be used to package medications, as they provide a secure and hygienic option that can protect the contents from contamination.

Household products:

Aluminum screw cap bottles can be used to package a variety of household products, including cleaning solutions, oils, and other liquids.

Overall, aluminum screw cap bottles offer a versatile and eco-friendly packaging option for a wide range of products, making them a popular choice for businesses across many industries.

V. Comparison with Other Packaging Materials

Here’s a comparison table between aluminum screw-top bottles, glass bottles, and plastic bottles:

| Aluminum screw cap Bottles | Glass Bottles | Plastic Bottles | |

|---|---|---|---|

| Material | High-quality aluminum | Glass | PET or HDPE plastic |

| Durability | Highly durable and resistant to corrosion | Fragile and susceptible to breakage | Durable, but less resistant to impacts and scratches |

| Weight | Lightweight and easy to transport | Heavier than aluminum and plastic | Lighter than aluminum, but heavier than plastic |

| Recyclability | 100% recyclable with an average recycling rate of 75% | 100% recyclable, but lower recycling rates than aluminum | Recyclable, but lower recycling rates than aluminum and glass |

| Environmental Impact | Eco-friendly and has a low carbon footprint | High energy consumption during production and transportation | High environmental impact due to its non-biodegradable nature and low recycling rates |

| Packaging Options | Available in a range of sizes and designs | Available in a range of sizes and designs | Available in a range of sizes and designs |

| Branding | Can be customized with branding and labeling | Can be customized with branding and labeling | Can be customized with branding and labeling |

| Cost | Moderate to high cost | Moderate to the high cost | Low to moderate cost |

Each type of bottle has its own advantages and disadvantages. Aluminum screw-top bottles are durable, lightweight, and eco-friendly, but can be more expensive than glass or plastic.

Glass bottles are environmentally friendly but are fragile and more expensive to produce and transport.

Plastic bottles are lightweight and cost-effective, but have a negative impact on the environment and are less durable than aluminum or glass. The choice of bottle material will depend on factors such as the type of product being packaged, the brand’s values, and the budget available.

The choice of bottle material will depend on factors such as the type of product being packaged, the brand’s values, and the budget available.

VI. Future prospects and potential growth in the market.

The market for aluminum screw cap bottles is expected to continue to grow in the coming years due to a number of factors:

Increasing demand for sustainable packaging:

As consumers become more environmentally conscious, there is a growing demand for sustainable packaging options.

Aluminum screw cap bottles are a popular choice because they are 100% recyclable and have a high recycling rate, which can help to reduce the environmental impact of packaging.Growing demand for convenience:

Consumers are increasingly looking for convenient packaging options that can be easily transported and consumed on the go.

Aluminum screw cap bottles are lightweight and durable, making them an ideal choice for portable and convenient packaging.Expansion of the beverage industry:

The beverage industry continues to expand, with new products and flavors being introduced regularly.

As a result, there is a growing need for innovative and eye-catching packaging options, and aluminum screw-top bottles are a popular choice because they can be easily customized with branding and labeling.Rising demand for premium products:

Premium and high-end products, including alcoholic beverages and cosmetics, require packaging that is both functional and visually appealing.

Aluminum screw-top bottles offer a sleek and modern appearance that can help to enhance the perceived value of a product.

VII. Conclusion

The future prospects for the aluminum screw cap bottle market look positive, with increasing demand for sustainable and convenient packaging options, as well as growth opportunities in the expanding beverage and premium product markets.

Custom & Wholesale Aluminum Bottles At Factory Prices, aluminumrock is a trusted and reliable partner for businesses in need of high-quality, sustainable aluminum bottle solutions.