The customization of aluminum containers in the cosmetics industry can provide a competitive advantage, enhance the customer experience, and support sustainability efforts.

Understanding the different printing solutions to customize aluminum containers is neck for your communication with suppliers.

I. Silkscreen Printing

A. What Is Silkscreen Printing?

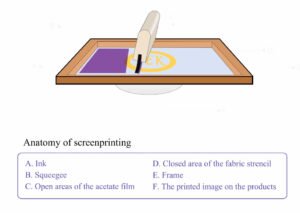

Also known as screen printing, is a printing technique that involves transferring ink through a mesh stencil, or screen, onto a surface.

The stencil is created by applying a photosensitive emulsion to the mesh and then exposing it to UV light through a film positive, which is a photographic image of the design that needs to be printed.

Areas of the stencil that are exposed to the light become hardened, while the unexposed areas remain soft and wash away when the screen is rinsed with water.

The resulting stencil has tiny openings that allow ink to pass through and onto the substrate when the squeegee is dragged across the screen.

Silkscreen printing is a versatile printing process that can produce vibrant and durable prints on a wide range of materials, including aluminum cosmetic containers.

B. Advantages of silkscreen printing

- High-quality and long-lasting prints

- Suitable for small-quantity printing

- Can print on various shapes and sizes of containers

C. Limitations of silkscreen printing:

- Not suitable for printing intricate designs or small text

- Not ideal for printing on large areas

- Time-consuming and expensive for large quantities

II. Offset Printing

A. What is offset printing

Offset printing is a printing technique in which ink is transferred from a plate to a rubber blanket, and then onto the printing surface.

The plate used in offset printing is usually made of aluminum or other materials, and the image is etched onto it using a photosensitive emulsion or other methods.

The ink used in offset printing is usually oil-based, and the printing process involves four main colors – cyan, magenta, yellow, and black – which are applied in layers to create a full-color image.

The ink is transferred from the plate to the rubber blanket, which then transfers it onto the printing surface.

Offset printing is a high-quality printing method capable of producing sharp, detailed images and text. It is commonly used in the printing of books, magazines, newspapers, and other high-volume printing jobs.

If you want to know other printing solutions, here is an article named 7 printing ways for your aluminum bottles for your reference.

In the context of aluminum cosmetic containers, offset printing is a popular method for customizing aluminum containers with high-quality, full-color designs.

It is often used for printing logos, branding, and other types of artwork on aluminum containers.

Offset printing is also suitable for printing on a wide range of container shapes and sizes, making it a versatile printing method for cosmetic packaging.

B. Advantages of offset printing

- Suitable for printing intricate designs and small text

- Suitable for printing on large areas

- Cost-effective for large quantities

C. Limitations of offset printing

- Not suitable for small-quantity printing

- Limited to flat or cylindrical containers

- Lower quality and durability compared to silkscreen printing

III. Comparison of Silkscreen Printing and Offset Printing

| Feature | Silkscreen Printing | Offset Printing |

|---|---|---|

| Print Quality | High-quality and long-lasting prints | High-quality and accurate prints |

| Suitable for Small Quantities | Yes | No |

| Suitable for Large Areas | Yes | Yes |

| Suitable for Intricate Designs | No | Yes |

| Suitable for Small Text | No | Yes |

| Cost for Large Quantities | Expensive | Cost-effective |

| Turnaround Time | Slow | Fast |

| Set-Up Time | Long | Short |

| Customization Options | Limited to certain container shapes and sizes | Suitable for a wide range of container shapes and sizes |

IV. Conclusion

Due to the advanced printing technology, you can have a very high-efficient cost with great quality depending on your need.

Aluminumrock provides mainly 7 different printing solutions for your aluminum bottles at affordable prices.