I think every buyer has a headache of looking for reliable suppliers. Even there are so many methods to find suppliers on platforms. it is still hard to verify whether it is a veteran supplier.

As a cosmetic packaging supplier with extensive experience, we have touched with so many buyers all around the world, we concluded some points they mostly cared about and listed the 7 must-know key points when you wholesale and customize metal cosmetic containers from China.

Below are the 7 must-know key points to import and customize metal cosmetic containers from China:

- Understand the supply chain, and location character of aluminum cosmetic packaging in China.

- Know about quality production management of metal containers.

- Consider them the certifications.

- Know their printing technology.

- Constantly follow up on the production progress.

- Require standard quality inspection.

- Standard aftersales claim policy.

Understand the supply chain, location character of aluminum containers packaging in China.

You Must Understand the supply chain character of aluminum packaging in China and where it is located.

In China, the Metal Product location is in Zhejiang, Guangdong, Jiangsu, Shandong, Hebei, Henan provinces.

that means you’d better find suppliers in those above provinces.

Here I just simply explain the advantages of Zhejiang and Guangdong province.

The quality of aluminum packaging in Zhejiang province is a little worse than quality in Guangdong province. However, the price is cheaper than the price in Guangdong province.

Know about quality production management of metal containers.

Do your best to know about how the suppliers manage the quality production of metal containers.

since the metal containers business is getting popular, more and more new incoming want a piece of pie, they are lack of management in production, printing control, you can imagine how sad it if you get unqualified products.

Normally, a manufacturer with standard quality management should have corresponding inspection standards and inspection records for raw materials to finished products.

Also, they should have a unique code and serial number for traceability for all accessories and semi-finished products.

Ask them how they manage quality control and production until you get all answers.

Consider them the certifications.

Consider if the suppliers have CE, ISO9001, SGS test reports, as that certification at least ensure they have passed the industry standard.

And It is better to take a video tour of the production plant so that make sure it is a real factory will work with you.

Know their printing technology.

Understand the printing level of the supplier, must make samples, test the printing effect and quality of metal cosmetic containers, cap fitting.

Except for the quality of aluminum containers, the printing quality counts more, best to know how they print or what machines they are using for 9 color printing if it is automatic or manual printing?

If manual printing, how to ensure the quality? Some factories use manual printing, that is why uneven colors appear in mass production.

Remember must require proofing, and check the bottle and printing quality yourself, as well as the cap fitting, almost all factories will Re-align the cap to achieve snug-fitting.

Constantly follow up the production progress

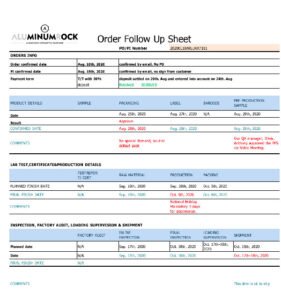

Constantly follow up the production progress, best to require the production video and photos to avoid their cheat. Yes, avoiding their cheat, some suppliers always excuse they are labor out, asking for leave, meeting, maybe you heard of more ridiculous excuses, the worst result is they postpone your delivery.

The meaning of follow-up is giving them pressure to produce your cargoes on schedule. (We update our clients follow up sheet weekly as a comprehensive system)

Require standard quality inspection.

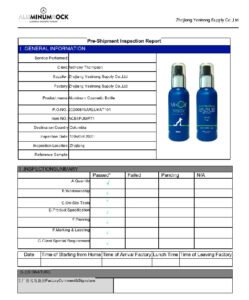

Find a very experienced supplier who can do the quality inspection, or find a third-party quality inspection company.

The very helpless phenomenon, even you go to a third-party inspection agency, there are many tricks. Some factories will bribe third-party inspection agencies even if the goods are not qualified, then third-party inspection agencies make a beautiful report for factories.

Therefore, it is best to find a supplier that has its own quality inspection team, they will pay more attention to quality. Ask them if they can provide their own inspection reports! If yes, it must be one of your qualified suppliers.

Standard aftersales claim policy.

Ask them if they have an after-sales claims policy, how do they compensate for quality problems.

The most headache thing is the worse quality when you get cargoes, and I believe no one likes a tug of war, so being clear of claims policy before cooperation will save you a lot of time and money.

3 Responses

Thanks for the great article.

Itís nearly impossible to find experienced people on this topic, but you sound like you know what youíre talking about! Thanks

Real excellent information can be found on website.Money from blog